Silica membranes

Development of silica membranes through the counter-diffusion chemical vapor deposition

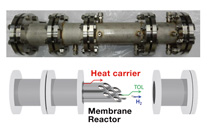

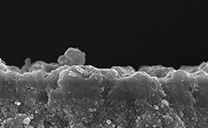

We are developing silica membranes for gas separation that are prepared by counter-diffusion chemical vapor deposition(CVD). This approach allows high-quality silica membranes to be obtained with high reproducibility. Membrane reactors have been also developed to investigate the practical use of the silica membranes produced by counter-diffusion CVD.

Zeolite membranes

Development of high-performance zeolite membranes

The uniform pores of zeolites allow them to be used as molecular sieves. It is possible to separate target components from gas or liquid mixtures using zeolites. We are developing zeolite membranes with various structures, and investigating their practical separation performance.

Palladium membranes

Development of pore-fill-type palladium-porous alumina composite membranes

It is known that palladium metal has the ability to absorb only hydrogen. Thus, dense palladium films can be used as hydrogen separation membranes. We are developing pore-fill-type palladium–porous alumina composite membranes, and evaluating their application in membrane reactors.

System design and simulation team

Development of membrane separation systems using various simulations

We design membrane separation systems by gas permeation simulations, perform diffusivity analysis by molecular simulations, and predict the atomistic structure of membranes by quantum mechanical calculations. Through comparison of simulation results with experimental data, we extract technical guidelines for membrane synthesis, and propose optimum membrane-aided separation systems.