- Biotechnology group>

- Approach

RITE molecular microbiology and biotechnology group is seeking solutions in tackling the environmental problems by taking advantages of the useful bioconversion capability of microorganisms.

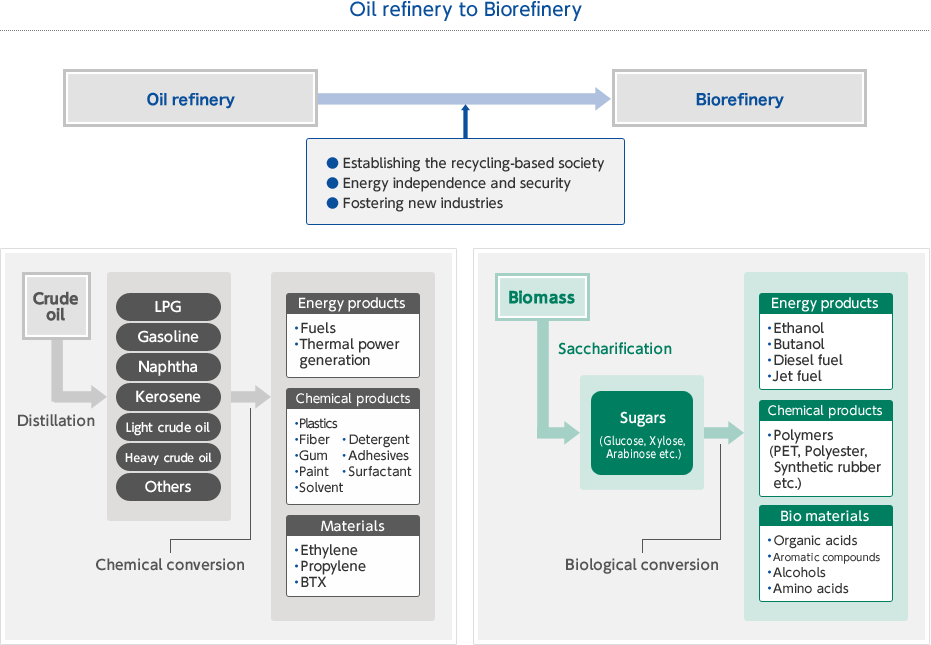

Molecular Microbiology and Biotechnology Group is working on the promotion of R&D of innovative biorefinery to contribute global warming prevention. The biorefinery encompass the technologies of industry and plants from which biofuel and green chemicals are produced using biomass as a raw material and it is expected the technology which preserves global environment. In the biorefinery, agricultural residues such as cellulose of corn stover and bagasse are converted to fuel (ethanol and butanol etc.) or high value and expensive chemicals (organic acids, aromatic compounds and amino acids etc.) by bioprocess.

Currently almost energy products such as automotive fuel and the electric power etc. and chemicals such as materials of cloth and plastics etc. in our familiar environment come from fossil resources (Oil-refinery). According to the biorefinery technology, we can produce many products as described above by using biomass as raw material as well as those which are made from oil by oil-refinery technology. Thus, constructions of biorefinery technology make our contribution possible to preserve global environment and promote a recycling-oriented society.

When we use a bioprocesss containing biochemical reaction such as microbial fermentation, enzyme reactor etc., it becomes possible to produce various kinds of chemicals by using the difference of biomass constitutions or chemical intermediates, and high quality of medical supplies with small-lot production, in addition to mass production of bioethanol. The biomass is plant origin, enabling a virtuous carbon-neutral cycle of plant growing, processing, harvesting, and burning, meaning that its use does not contribute to net changes in the level of atmospheric CO2.

Therefore the biorefinery using biomass can contribute to global warming prevention by suppressing CO2 emission derived from consumption of fossil resources. The biorefinery also activates regional agriculture by raw material production and reduces import volume of fossil resources from foreign countries at the same time, contributing to our countries' energy security.

In a bioprocess, first of all, the cellulosic biomass is saccharificated to convert to mixed sugars by enzyme such as cellulase. Then, the mixed sugars are converted to each products in a next step of the bioprocess. In current biorefinery, corn, sugarcane and soya bean etc. are typical raw materials for bioethanol and biodiesel production; however they compete with food resources in recent years and there is criticism which causes soaring of crops and vegetable oil prices. Therefore, technology development of utilization of a cellulosic biomass as raw materials has rapidly proceeded to avoid the competing with food resources.

In foreign countries, USA achieves the biggest biorefinery industry in the world, and in particular it accounts for about 60 % of the world bioethanol production (13.5 billion gallon at 2013). Since ca. 40% of the US corn production is used for the raw material of bioethanol production, large scale cellulosic ethanol plants (around 20 million gallon) have been opened in by using corn stover as a raw material according to a strong support of the US government. From the US energy policy aspects, the Renewable Fuel Standard (RFS) mandates 36 billion gallons of biofuels to be produced by 2022 based on the Energy Independence and Security Act of 2007, in which 15 million gallon of corn based biofuel should be kept after 2017 and 16 million gallon must come from cellulosic biofuels by 2022.

In Europe, about half of the car has a diesel engine and consumption of biodiesel has been much increased than that of bioethanol. About 9,000,000 tons of biodiesel was produced from rapeseed, palm oil etc. in 2012. A target volume of biofuels established in 2009 was 10% of the transportation fuels used in Europe by 2020. However it was decided by the EU committee in 2013 to restrict the use of biofuel made with agricultural products directly (1st generation biofuels), such as rapeseed biodiesel and corn ethanol etc. because the increase of these biofuels was considered to lead to soaring of food prices and environmental pollution. Therefore, the 1st generation biofuels are planned to restrict to the volumes of 6~7% of the transportation fuels used in Europe by 2020. In addition to the US, bioethanol is produced by sugarcane in Brazil and soybean oil is produced in Argentina, and China and South East Asia also increase the bioethanol and biodiesel production.

Finally, we introduce status of green chemical production. In spite of its lower production volume than that of biofuels, the green chemical production is being increased steadily. Typical bioplastics, corn-based polylactic acid (PLA) is produced commercial scale by the plant with a capacity of 140,000 ton per year in the USA. PLA having properties equal to commodity plastics in addition to its biodegradablility has been also developed, and the 2nd large-scale PLA plant construction is planned. Non-biodegradable polyethylene, which made from ethanol-dehydrated ethylene, has been produced with the level of 200,000 tons from 2010 in Brazil, and it is used for a food container etc.. In the field of polyester, technology development is advanced to synthesize bio polyethylene terephthalate (bio-PET) from the terephthalic acid made from the biobutanol and ethylene glycol derived from bioethanol. In other expectable bioplastic, technology development of bio-based engineering plastics such as nylon, epoxy resin etc. is also reported.