- Home

- Solid Sorbents

Solid Sorbents

Description of the Research Areas

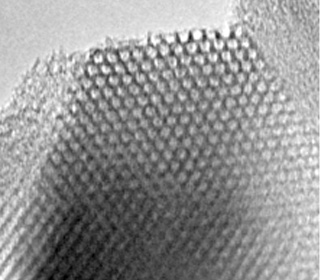

The standard CO2 capture process employing the amine solution absorption method is fairly energy intensive, since it requires heating to regenerate the absorbent. Other drawbacks of this technique include equipment corrosion and amine losses due to the high volatility of these compounds. The conventional Pressure Swing Adsorption (PSA) process using Zeolite 13X is also energy intensive, since regenerating the absorbent requires modifying the partial pressure of CO2 by application of a vacuum. Additionally, a dehumidification process that consumes approximately 30% of the total process energy is necessary during a typical PSA process using a hydrophilic zeolite because water vapor has a higher affinity than CO2 for the zeolite surface. Therefore, a new sorbent that preferentially adsorbs CO2 in the presence of water vapor is desirable to allow the development of a simple, energy-efficient CO2 removal process that eliminates the dehumidification step.

Recently, amine-modified solid sorbents, such as polyethyleneimine (PEI)-loaded silica, have become of interest due to their apparent advantages over the amine solution absorption method with regard to post-combustion CO2 capture, since the use of these sorbents mitigates the above drawbacks. Thus, a new project aimed at developing a novel solid sorbent for post-combustion CO2 capture with reduced energy requirements was initiated in Japan in 2010.